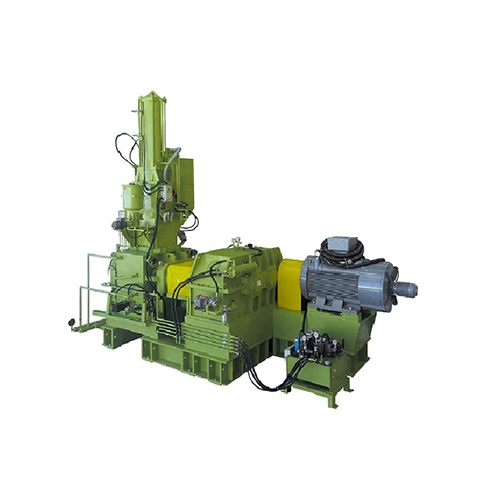

Intensive Mixer

Categories : Rubber Mixers

Compounding For Rubber、Plastic & Chemical Industries Features: 1.Rotors: Two wings design with good cooling design. Excellent cooling ability. Anti-wearing treatment on the surface. 2.Chamber: Drill hole type jacket. Excellent cooling ability. Material contact surface: Hard chrome plating and fine polish. 3.Discharge door: Excellent sealing. No material leakage. 4.Ram: Drive by air cylinder. Good mixing and dispersion quality.

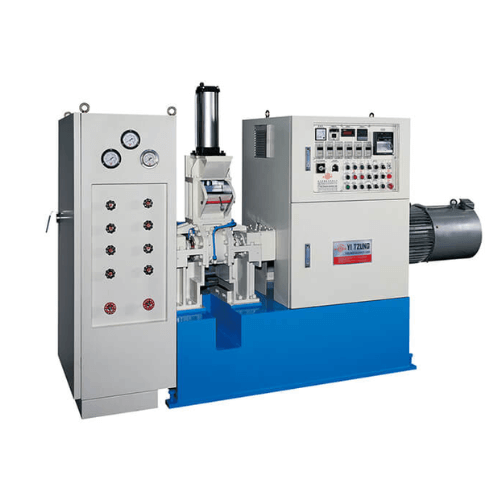

Super Mixer

Categories : Rubber Mixers

Our company has designed & produced two model mixer- KCA: Adopts fixed rev. speed motor drive which suitable for general material mixing. KCB: Adopts pole change 2 steps speed motor drive which suitable for large volume material mixing. Options: This KD pellet line is designed to provide automatically rubber pellet making line. It includes : Auto Weighting-->Mixing-->Extruding-->Pelletizing -->Cooling-->Screening& Storage.

Intensive Mixer

Categories : Rubber Mixers

This Intensive Mixer is designed for mixing compounds and specific plastic. The structure of the machine consists of the main air cylinder, floating weight, feeding door, mixing chamber, rotors and discharge device. When performing mixing compound operations, the material and ingredients are fed together into the mixing chamber. The material in the mixing chamber is repeatedly sheared and squeezed by the rotors. This provides a series of chemical rotations between the material and the ingredients, which enables the material pieces to stick together into a paste mass shape. Mixing compound operations are performed according to the set temperature and conditions. This specially designed mixing machine provides efficient mixing and refining for a wide range of raw materials, such as raw rubber, resins, asphalt, cellulose, PVC ane EVA…etc.

Twin Taper Screw Roller Head Extruder

Categories : Rubber Extrusion Lines

MACHINE FUNCTION: The Twin Taper Screws Roller Head Extruder consists of two tapered screws and two rollers,The machine is normally applied for processing to a dispersion kneader or an intensive mixer. The rubber material,mixed by a dispersion kneader or an intensive mixer,is then fed to the rollers through the two tapered screws.It calenders the material to a desired sheet form at a constant speed. The machine is designed and engineered for high speed sheet forming operations

Laboratory Intensive Mixer

Categories : Dispersion Kneaders

The 1.8L Laboratory Intensive Mixer is designed for material research and develpment applications in the laboratory. The heating chamber (mixing chamber) and rotorsave built with water circulation sleeves assuring excellent cooling affect and heat transfer efficiency.

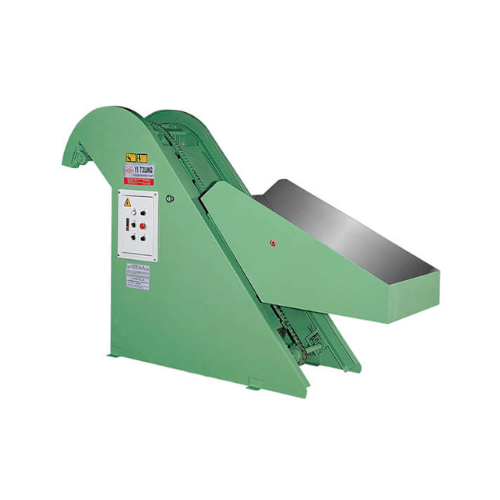

Ket Conveyor

Categories : Loaders and Conveyors

This bucket conveyor is suitable for locating between the Dispersion kneader and the Intensive mixer etc. providing material supply function. Eliminates troublesome manual infeed of material. Labor saving while increasing working efficiency. Simplified construction; maximum stability; easy maintenance.

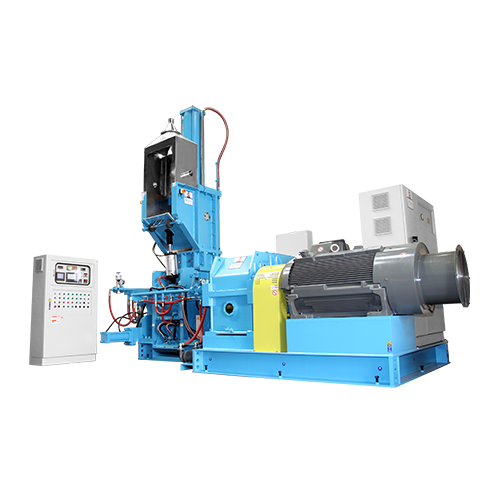

Air / Hydraulic - Intensive Mixer (BANBURY)

Categories : Rubber Mixers

Improve Compound Shearing Force And Superior Dispersion For Curing Process Low Temperature Mixing